Form-tactility in 3D Printing Technology

2018

School Project

Contextual Design

Design Academy Eindhoven

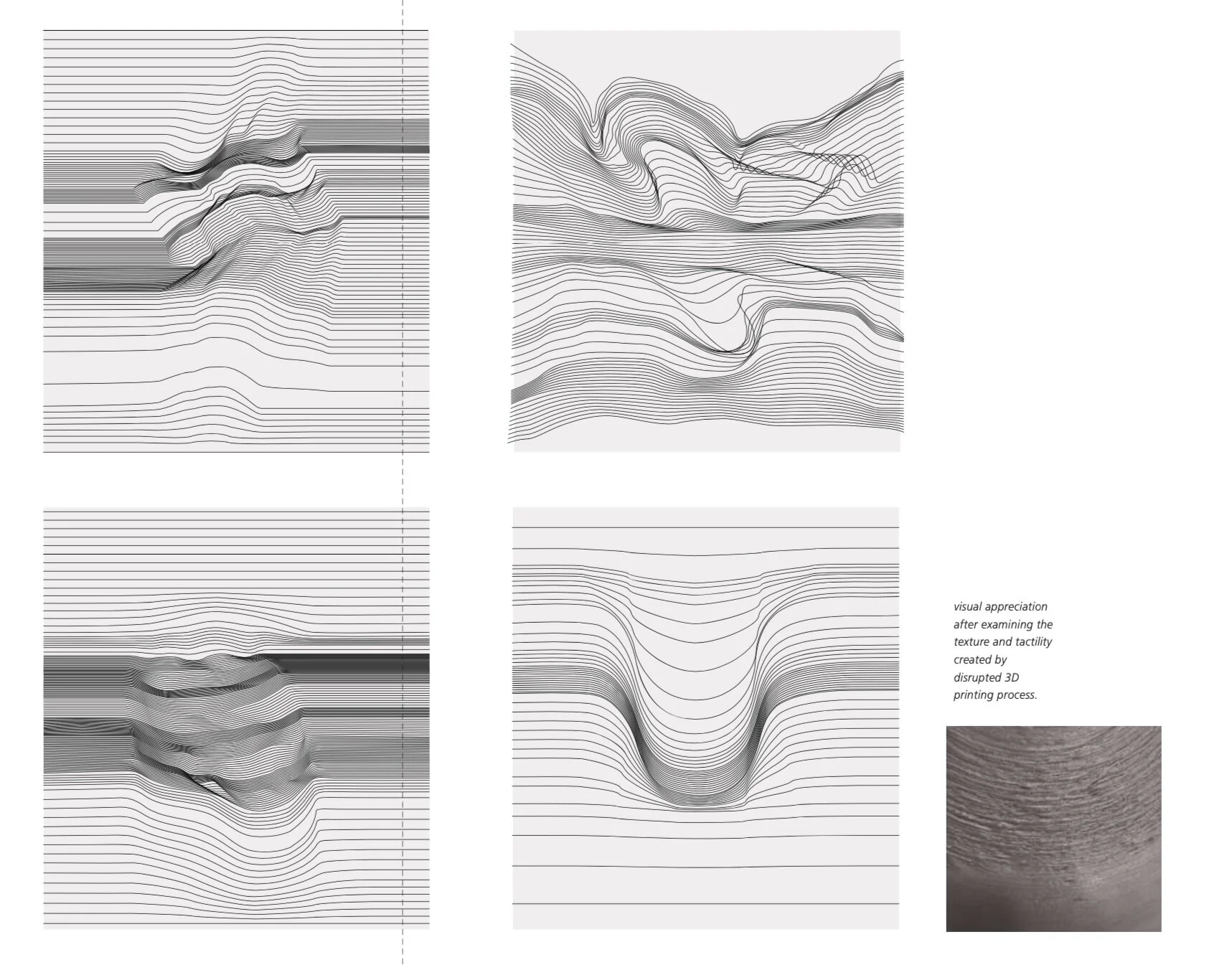

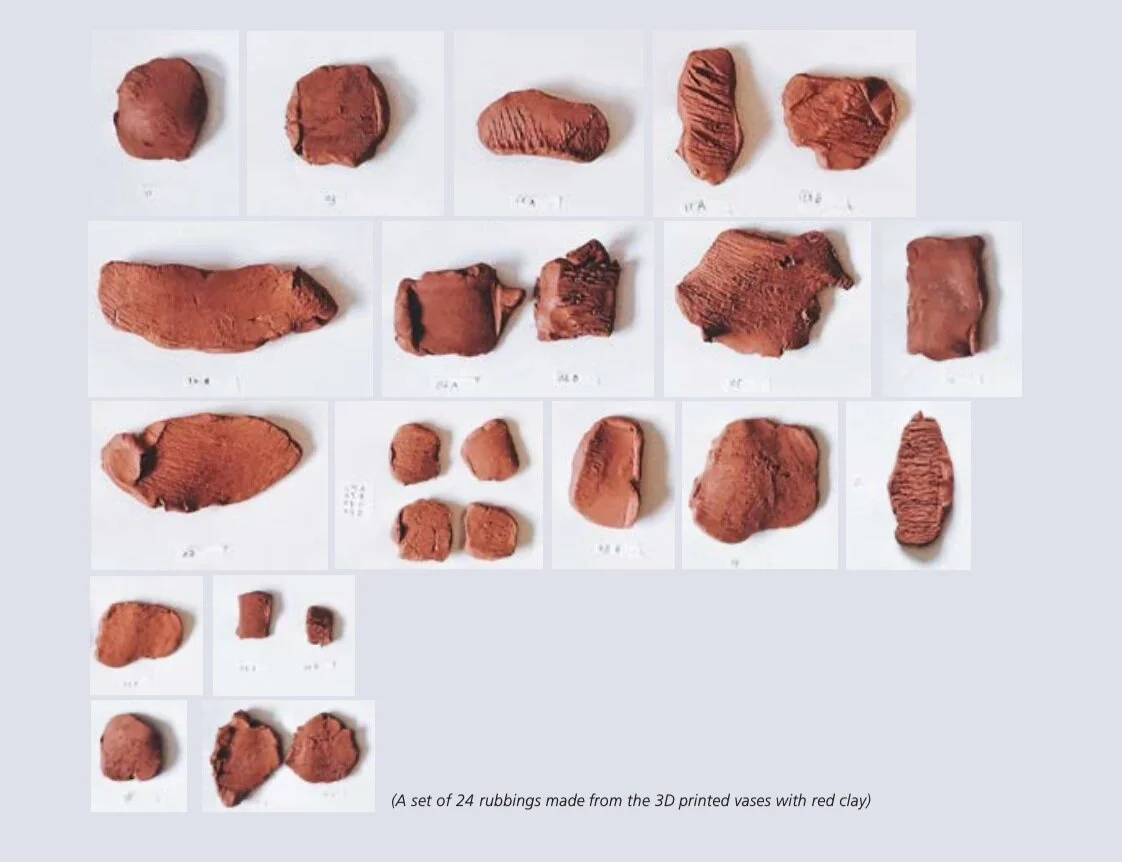

This is a set of vases designed to show and compare different ranges and densities of the tactile textures caused by not turning the cooling fan on during 3D printing process. (creating a controlled error in the printing process). With the cooling fan off, the surfaces’ tactility of the printed prototype would be influenced by the angle of lines, the thickness of the walls, and the degree of curvatures drawn in the 3D software.

As shown on the table, the model with a bigger degree would be much more tactile than a plain cube while a revolved model would barely have any tactile quality. I use the dynamic balance between the form and the tactile to design this set of vases.

Forms Follow Failures

The shapes of the vase series are primarily relate to human errors or malfunctions of the 3D printer. The angles of the shapes have influences in certain kind of printing situations: for instance, not having a proper cool down could cause more shape distortions on a triangle more than a cylinder.